-

Morton Mill – Repair

It takes BIG machines to do repair work on other BIG machines…. Thus is the case for this customer, who specializes in repairing and servicing…

-

Custom Lathe – Retrofit

A perfect example of a tailor-made retrofit to suit a custom-built machine.

-

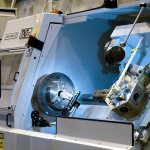

Wintec CNC Lathe – Repair/Retrofit

Whenever we hear ‘machine crashed’, we understand the challenges ahead…. Such was the case with this Wintec Lathe that had ‘some mechanical repairs’ but was…

-

G&L Orion Mill – Rebuild/Retrofit

This BEHEMOTH of an old, rundown machine was being moved from one customer facility to another…. Job One? Clean it up and make it run! …

-

Mori Seiki Lathe – Rebuild / Retrofit

This old, dysfunctional machine was completely restored for reliable production, including a new CNC control, new electrical, and new lube system.

-

J&L Slant Bed Lathes – Rebuild / Retrofit

Peiffer completed this intensive rebuild and retrofit program for three (3) machines in six months.

-

Landis Grinder – Rebuild / Retrofit

From warehouse storage to enhanced functionality, this “from the ground up” rebuild and retrofit brought new life to a “good, old machine”.

-

Custom Grinder – Rebuild / Retrofit

This one-of-a-kind machine received all new controls, as well as many new updated system components, for easier, more efficient operation on the production floor.

Rebuild / Repair / Retrofits

In our line of work, the “three R’s” – Rebuild, Repair, and Retrofit – often go hand-in-hand, as machines are restored to “good working order”, according to customer specifications. Find out more about our Machine Tool Rebuild, Repair, and Retrofit services »